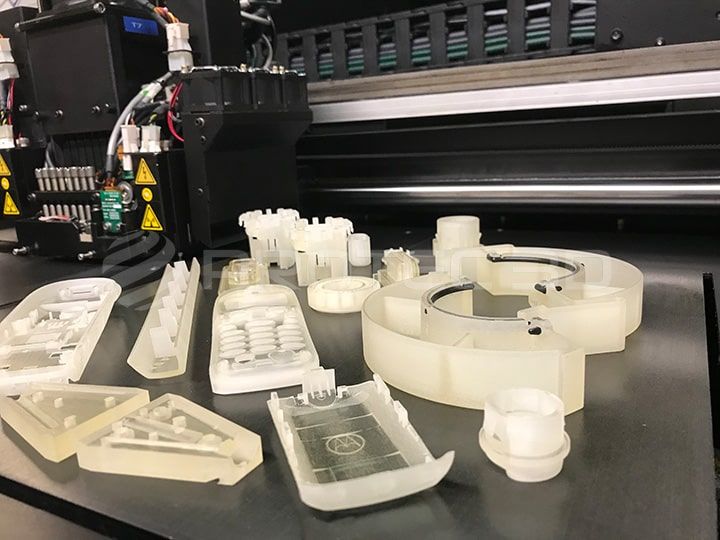

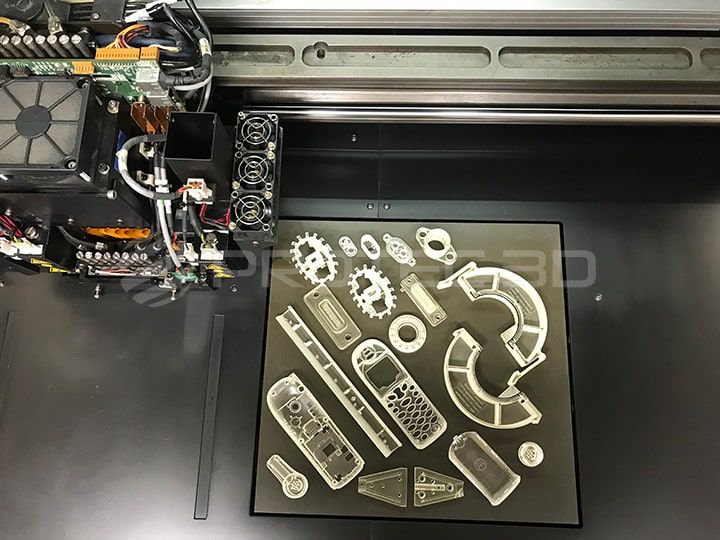

PROTEC3D stands for outstanding quality in Multi Jet Modeling (MJM) 3D printing. With our MJM 3D printing service, we realize sophisticated 3D printed prototypes and illustrative models from a variety of combinable photopolymers with impressive attention to detail.

Our MJM 3D printing process guarantees a smooth realization of your project from the initial idea to the high-quality end product. Our expertise and experience support you in all phases of product development.

Protec3D has been a very reliable and trustworthy supplier which we in ZiaDent Sweden AB would highly recommend! The products are high quality and sustainable.

A company that offers high-quality materials combined with a profile of professional seriousness, where it meets delivery times and is committed to monitoring customers and ensuring their satisfaction. Absolutely recommendable

Super quality, super service. Even for very short-term projects on our part, we could always count on Mr. Reizner & his team.

Many thanks for the fast and high-quality service. Gladly again at any time!

The Multi Jet Modeling (MJM) process, also known as PolyJet technology, is characterized by a precise and detailed printing process. The process is structured as follows:

This process enables the production of prototypes and end products with exceptional attention to detail and a variety of material properties.

By meeting these requirements, users can take full advantage of the MJM process and produce high-quality, customized parts and products.

MJM is ideal for applications that require maximum accuracy. You can find an overview of the many possible applications here:

Features: Robust, flexible and versatile.

Properties: For the most diverse requirements in terms of aesthetics and functionality.

Properties: For the production of gaskets with different degrees of hardness.

Use the advanced Multi Jet Modeling technology for your next project. As a 3D printing service provider with over 10 years of experience, we know exactly what is important. Contact us today and accelerate your product development.

MJM is a 3D printing process that applies fine layers of liquid photopolymer resin and cures immediately with UV light to create precise and detailed models.

In contrast to processes such as FDM or SLS, which melt or sinter material layer by layer, MJM enables printing with multiple materials in a single process and achieves very smooth surfaces and complex geometries with fine details.

The cost can vary depending on the size, complexity of the part and materials used. In general, MJM prints are in the higher price segment due to the high-resolution level of detail and the possibility of using different materials.

Designs for MJMs should take into account the ability to create complex geometries and cavities, while also considering the need to remove support material and material properties.

The core idea is to pass on our knowledge and to convey the possibilities of 3D printing processes.

The range of applications for 3D printing is now almost unlimited!